buiboy

Junior Member

Posts: 71

|

Post by buiboy on Nov 2, 2014 6:47:38 GMT -6

Late Aug. 2013 Base after compacting first lift of gravel.  First 6" of material  Building up material and compacting around the edges.  More edge work.  Inside looking back to front  Outside looking in. First 6" of base compacted.  More to follow. |

|

buiboy

Junior Member

Posts: 71

|

Post by buiboy on Nov 2, 2014 7:03:27 GMT -6

Aug. 2013 continued. 12" of gravel now packed in place.  My wife was the official compactor. Did a great deal of it by her self.  She said on the hot summer nights, it felt cool on her bare feet.  |

|

buiboy

Junior Member

Posts: 71

|

Post by buiboy on Nov 4, 2014 16:24:32 GMT -6

September 2013 First lift of the upper layer being put down.  This will be a Monolithic slap or as some call them an Alaska floating slab. 12" thick on the edges and 6: think everywhere else.  Working my way back out the north bay.  The tractor does the heavy lifting but there is still a lot of shovel & rake work that had to be done.  Mike |

|

|

|

Post by Dave on Nov 4, 2014 18:03:06 GMT -6

Looking good.

|

|

buiboy

Junior Member

Posts: 71

|

Post by buiboy on Nov 5, 2014 16:19:56 GMT -6

Thanks Dave. Top 6" of gravel now laid down and compacted in multiple layers. 4 legged supervisor checking for level.  Northwest corner view  Southwest corner  Back side (East). One sliding door removed in preparation for concrete.  Getting close now. I was excited to have a floor that the weeds didn't grow in. |

|

buiboy

Junior Member

Posts: 71

|

Post by buiboy on Nov 8, 2014 15:47:09 GMT -6

Time for forms  North bay  View from front  North wall  Back doorway  View from back doorway  |

|

buiboy

Junior Member

Posts: 71

|

Post by buiboy on Nov 10, 2014 16:55:09 GMT -6

|

|

buiboy

Junior Member

Posts: 71

|

Post by buiboy on Nov 10, 2014 17:05:16 GMT -6

Oops, I got fat fingered and selected "Create Post" before I added any text. Oh well it's not like I had much to say anyway. For the most part the floor looks fine. I wasn't terribly impressed with the contractor but what can you do. One more photo. ![]()  |

|

|

|

buiboy

Junior Member

Posts: 71

|

Post by buiboy on Nov 17, 2014 17:26:16 GMT -6

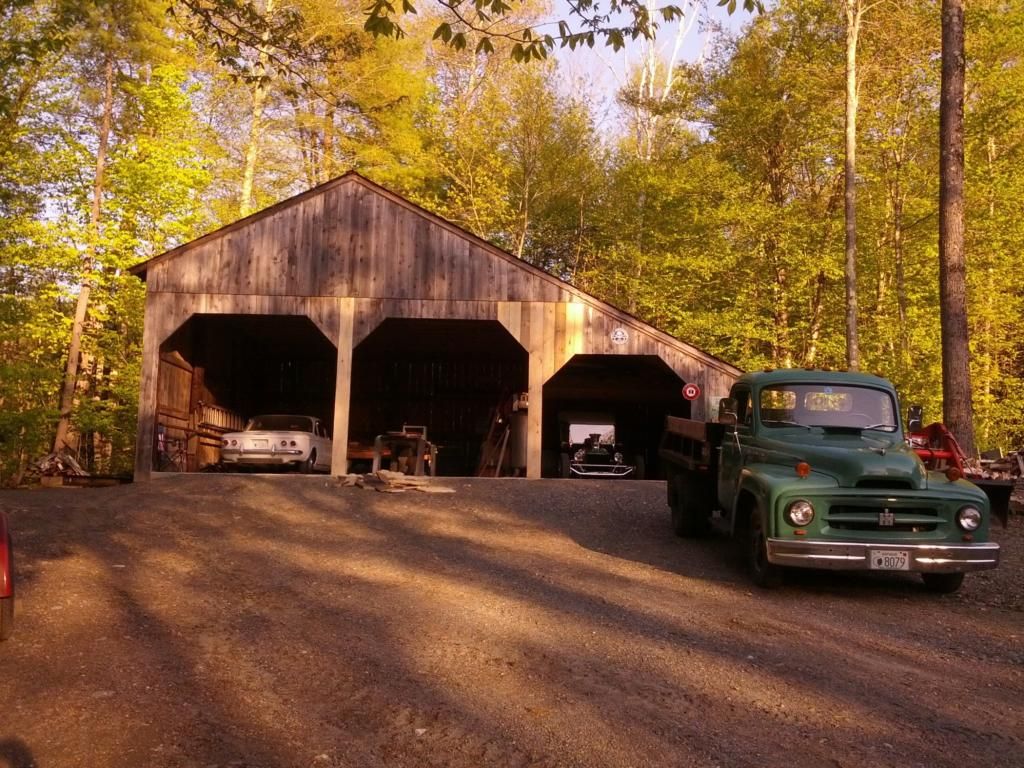

May 2014 I decided we needed doors so started the framing and preparations. As I mensioned in a previous post, I'm out of hemlock so decided to purchase some white pine from a local mill.  Had to replace some damaged and poorly planned boards. As you can see I added to the herd. Bought my wife a 1961 Corvair hard top, Monza 900. Nice little car, 35k miles original.  I decided the main doors would be hanging sliders. Overhead rail hung and trim work started.  Grass needs to mowed but that's what happen when you get focused on a new project. |

|

|

|

Post by Dave on Nov 17, 2014 17:59:21 GMT -6

Great posting. Keep those pictures coming, please.

|

|

|

|

Post by ohiosam on Nov 18, 2014 12:14:52 GMT -6

Great looking barn, I've enjoyed watching everything come together.

|

|

buiboy

Junior Member

Posts: 71

|

Post by buiboy on Nov 19, 2014 16:39:03 GMT -6

Thanks Dave & Ohiosam. Great praise coming from you two. Replaced some boards and framed in the poles. Trimmed the openings and hung the door track.  Wee-Hawker staging. Drives my wife nuts because I have 18 sections of Vangaurd staging, the real stuff.  Let's stand back and make sure everything looks okay. Notice that you can look right through the back wall. I think the next project will be battens once I finish the doors.  It's almost time to start building doors. |

|

|

|

Post by tarnished on Nov 21, 2014 6:25:02 GMT -6

Buiboy, Great Job!!! Love the barefoot compactor.  That slab is HUGE. Why so thick? No danger of the huckster falling through. Notice you have the compressor in there, what will the barn be used for? Storage only, or shop space also? Why did you not use more Hemlock for the rest of the siding? Could you not have had sawmill cut you some more, or just not available? Are you planning on natural weathering, or some type of finish for the siding? Really a good feeling when the floor goes in isn't it! Thanks for the update, enjoy following along. Rusted |

|

buiboy

Junior Member

Posts: 71

|

Post by buiboy on Nov 21, 2014 16:30:23 GMT -6

Buiboy, Great Job!!! Love the barefoot compactor.  That slab is HUGE. Why so thick? No danger of the huckster falling through. Notice you have the compressor in there, what will the barn be used for? Storage only, or shop space also? Why did you not use more Hemlock for the rest of the siding? Could you not have had sawmill cut you some more, or just not available? Are you planning on natural weathering, or some type of finish for the siding? Really a good feeling when the floor goes in isn't it! Thanks for the update, enjoy following along. Rusted We (concrete contractor & I) were concerned as how the slab would react with the telephone pole foundation. He suggested that we wrap the poles with this expansion material and pore a monolithic style slab. He said it would never crack. Guess what...he was wrong. I'm not sure I even know anymore what the barn will be used for. I never thought It would ever have a concrete floor or doors but look at it now. The original plan was to store the tractor, old IH truck and a few implements but I've re-purposed it to be a storage and maintenance facility for seasonal autos as well. I have a heated two car that I use as my primary shop for most fabrication and restoration projects but I do use the barn for some of the same things. You never have too much weather-proof space. The original hemlock was sawn at a family mill that is no longer in service. The local mill didn't have any hemlock and I didn't want to wait for some to be processed. I will let it all weather naturally. The pine is already starting to turn that barn board grey. Thanks for your interest. I'll be sure to post more updates. |

|