chaz

New Member

Posts: 22

|

Post by chaz on Jan 18, 2013 18:28:57 GMT -6

New here! Thanks for putting up the site. I live in a "new" barn that looks like it might be from years ago. Built it ourselves over a period of several years.  |

|

|

|

Post by Dave on Jan 18, 2013 19:19:11 GMT -6

We moved this post to it's own thread.

chaz, we hope this was ok with you.

This is one of the most remarkable builds that we had the privilege of following on the GJ.

More pictures for the members that will want to see it on here, please.

|

|

chaz

New Member

Posts: 22

|

Post by chaz on Jan 18, 2013 21:35:50 GMT -6

I have a friend who inherited the family ranch here in Montana. Its been in her family for I think 5 generations. There is a remarkably beautiful barn on the property that was built in the early 20's. It is completely unmolested, even down to the percherons' plowing collars and other gear.

I'm a city kid, but was so taken by that barn that I promised myself that SOMEDAY I would live in a barn. I'm 64 now, and two years ago my wife and I decided that it was time. We retired, She sold her business and we built the above barn.

Now most folks look to downsize as they get older, but we really needed an adventure. We aren't all that fond of travel , vacations etc.

We like gathering with family and friends over a good meal and sharing lighthearted conversation . This is the perfect place for us. I step through a door and I'm in my shop... So convenient. Very little if anything would we change.

I'll post a bit each day so it'll seem like a tour. Hopefully you'll check back and follow along.

|

|

chaz

New Member

Posts: 22

|

Post by chaz on Jan 19, 2013 10:01:11 GMT -6

THE BACK STORY We lived in our old home for 38 years. It was a nice home with a detached two car garage that I had converted to my workshop.  There was a lot to like about it. It was tiny, with a footprint of about 1000 sq ft. We dont need a lot of space to live in, and we finished the basement to give us room for guests. The shop was a different story. I needed more space, so eventually we purchased a warehouse about 11 miles from our home.  It wasn't much to look at from the outside, but it was huge! 16 foot ceilings and 2,500 feet of floor space with a storage loft. I set to work, and made a small " city" inside the shop complete with a diner, whorehouse, fire station, dentist office, toy store and a floral shop. This became my workshop for the next five years.  There were two big problems. All my tools were eleven miles out of town, and it was easier to say "I'll wait till tomorrow to fix that" than to get in the car to drive a half hour to get what you needed. When its 15 below zero , its not just a quick hop. The second problem was that the warehouse was a pole building, and in the winter the floor was so cold your feet would hurt. I found it a lot easier to turn on the TV after dinner and waste the evening rather than bundle up and head out to the shop. My wife loved her house and was in no hurry to move. "It'll take something special to get me out of my home" she'd say. One day something special happened. I found an acre lot that was a former truck farm. A small dilapidated home sat on the property together with outbuildings. Topsoil about 3 feet deep with the land sloping gently to an irrigation ditch in the back.Totally private and screened by trees along the property lines. I called my wife out to see it. "Well, you found it" she said."I hope you're happy" I was. Our offer was accepted . The "Farm" would be a reality. Now planning would begin. |

|

|

|

Post by Linda on Jan 19, 2013 16:50:15 GMT -6

Hi Chaz,

I love your "little house", it looks like a happy home. But, looking ahead, to your beautiful barn house, this is truly a happy place. It is an amazing build. Dave says you will have interior pictures, to show, I am eager, to see them.

|

|

chaz

New Member

Posts: 22

|

Post by chaz on Jan 20, 2013 16:38:51 GMT -6

The actual planning took most of the first winter. We discussed our needs. I needed s warm shop with good lighting. My wife wanted a comfortable , relaxed home. It'd been so long since we used a garage to park our cars in that such a thing seemed like a real luxury. I downloaded a little cad program called DELTACAD and taught myself to use it. Each evening my wife and I would sit down and try to imagine how to get all this in one building without making it look like a big box store. It looked like we needed about 6000 sq ft under roof. The idea of a barn seemed like a natural . We both love monitor style barns, and I had seen some stone silos on barns back East that just blew me away... Why not? Once decided, the classic monitor barn became the form of our dream. I didnt want to screw up the form by moving windows,doors, etc to our liking. Whatever we wanted would have to fit inside the classic shape- not alter it. The upper windows would stay evenly spaced, and the interior would have to accomodate that classic form. The house has no front door. All our friends always just walked in the back door and said Hi. This wouldnt change. No one ever came to our front door but solicitors. We just didnt need it. The "back" of our house faces the street. Why do we want to look out our windows at a street when our backyard is so beautiful? The house would face backwards. There would be separate heating units for the shop and house so that transfer of shop smells would be minimized. Heating would be done by Gas Forced Air. Not floor heat. In Montana temps can vary 50 degees in a day, and floor heat is slow to react. There is no air filtering with floor heat, and air conditioning is easy to add to forced air systems. Slowly the plan took form and I completed the plans. Off to the floor and truss engineers they went. ..  I wanted the shop to be clear of posts. The structural guy explained to me that wasn't going to happen! "Think of it this way" he said  Imagine two people sitting in chairs back to back. A board is stretched across the backs of the two chairs and a third person is standing on that board. The people represent the load on your roofs. Now cut the back legs off both chairs...  Almost ALL of the roof loads are concentrated where the red circle is.. Not only would I need posts, but some hellacious beams to support the load. It was literally back to the drawing board. I decided I could live with 4 posts in the shop area. The glu-lam beams would be 6 inches wide and 24 inches deep. I figgured it out so that they would be hidden in the upstairs walls. In a few weeks the plans were approved and work could begin. |

|

|

|

Post by tarnished on Jan 22, 2013 19:15:20 GMT -6

Chaz, WOW. Just WOW. Love your old house! Would have been hard to leave. But your new digs are just something else. I cough your post before, and can't wait for your updates here. Your so lucky to start fresh and new.....

What did you do with your warehouse? It was sure sum thing to see also. Hope you post it up here also. We all love to see ;D

|

|

chaz

New Member

Posts: 22

|

Post by chaz on Jan 22, 2013 22:03:37 GMT -6

What did you do with your warehouse? It was sure sum thing to see also. Hope you post it up here also. We all love to see ;D I still have the warehouse. I use it for storage of my stuff. I'm a collector.... Some say "hoarder". I'll show some of my projects and collectons later in the story.. We decided to do everything ourselves except excavation ( I dont own a backhoe), Concrete, (I dont own forms, and I panic at anything over 4 cubic yards) , The finishing of the sheetrock mud, and the heating systems. To make sure I dont have a cold shop floor ever again, we poured four foot deep frost walls around the whole shop. Then we insulated that with foam sheets. I didnt put insulation under the shop slab cause I was afraid it might compress under heavy load and the floor would crack. After the excavation and concrete, we started framing. Myself, my buddy Dana who just got laid off from his job of 30 plus years when the mill closed, and my cousin Mike who is disabled, but helped out where he could -- and let me tell ya he helped a lot! The walls were framed in 2x6 10 feet long. the outside sheathed in 1/2 in OSB. The long wall is just shy of 90 feet.  I'd never taken on a project this size, and the trucks just kept rolling in full of materials. It was almost depressing. Thankfully the guys have a great sense of humor so we usually laughed our way through most days. Once the shop walls were up it was time for the beams. The beams were sumpin' else.... 6 wide by 24 deep by over 40 ft long. .. Here's Dana setting one in place.  There was a lot of satisfaction when those were finally up. |

|

|

|

Post by crazytrain on Jan 22, 2013 23:52:29 GMT -6

Wow, I am looking forward to seeing the rest of this build. The Barn/house is a very cool idea. I wish I could get my wife to agree to something like that.

|

|

chaz

New Member

Posts: 22

|

Post by chaz on Jan 25, 2013 21:03:16 GMT -6

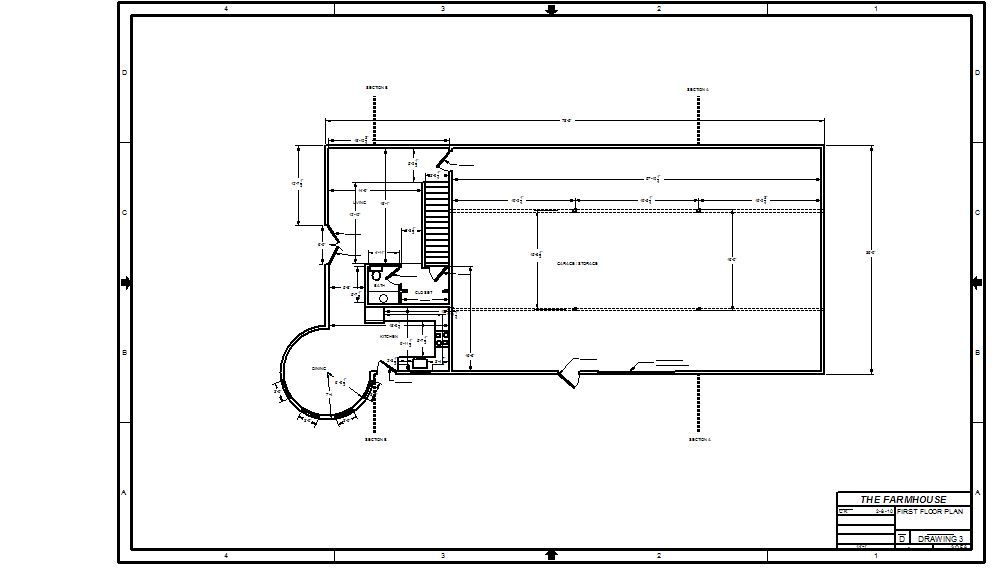

There were over 120 roof trusses total. A monitor barn has a lot of roof. Thankfully none of the trusses were huge.This is because there are 3 roofs, The upper main roof, and the two lower. The curved glu-lam we built ourselves, by bandsawing sections of 1 x 12 and gluing them into the arc.  The North (left) 20 feet of the main floor is home, as well as the entire top floor. The silo is 3 stories tall. It's part of the "drive under" garage on the lowest level, dining room on the main floor, and office on the uppermost floor. Here's the floor plan of the main floor.  I had done some stonework on this little rental we built, and I became fascinated with that medium.  What if the whole exterior of the silo were done in stone? Sometimes there's no one nearby to stop me when I go off on my architectural flights of fancy. Sometimes that's a good thing. (sometimes not) Here's a picture of things getting complicated. It was official. We were in over our heads!  Moderators: If I'm getting too long winded here its OK to let me know. There is a short version. I apologize if I'm using too much bandwidth. |

|

|

|

Post by Dave on Jan 25, 2013 23:35:05 GMT -6

chaz

I looked this up in the Proboard help section as to how much broadband is available to us. The following is a copy of their statement.

"With ProBoards' free forum hosting service, there are no limits on bandwidth, the size of your membership, number of discussion threads, or forum activity levels. You are welcome to build a community of monumental proportions. Our forums are built to scale for large communities!"

So be our guest and show us as much as you want. Love to have you sharing this with all of our members.

|

|

|

|

Post by tarnished on Jan 26, 2013 6:47:32 GMT -6

Chaz: Great build, can't wait for more pics. You will probably tell us, but what were the curved glu-lam's for? Stone rental is to nice to rent. You must have special tenants!  Is the siding stucco? And did you do it your self also? John |

|

chaz

New Member

Posts: 22

|

Post by chaz on Jan 27, 2013 10:26:46 GMT -6

It became apparent real fast that the silo was gonna take a LOT of time. I cut the sill plates from 3/4 inch treated plywood with a trammel board attached to a router . I knew this would make them perfectly round . The studs were placed on 12 inch centers, and we bent quarter inch plywood around that- glued to the studs and attached with screws. This literally took about a week to just get the main floor round completed to the sheathing.  The top floor was even more difficult as we were now 20 feet in the air.We finally built the round in six separate sections and slid them out from the inside and attached them. Now how the hell were we going to do the roof at 35 feet up? We decided to assemble the roof on the ground and have it craned into position- an expensive but safe choice  There are 32 trusses in the roof   Kinda looks like a spaceship, dont it? |

|

chaz

New Member

Posts: 22

|

Post by chaz on Jan 27, 2013 10:35:58 GMT -6

Chaz: Great build, can't wait for more pics. You will probably tell us, but what were the curved glu-lam's for? Stone rental is to nice to rent. You must have special tenants!  Is the siding stucco? And did you do it your self also? John The curved glu-lam is to go upstairs where the bedroom enters the silo. I wanted the ceiling to be uninterrupted by bracing and this allowed me to accomplish that. I discovered that high end small rental homes is a great niche market. They bring super rents and responsible renters. Yep, it is stucco... our first attempt. Stucco is AMAZING stuff! My next rental will be an all stucco free form home. |

|

|

|

Post by tarnished on Jan 31, 2013 19:34:35 GMT -6

Chaz: So your saying that the glu-lam went in as we see it in the photo. (laying down) Not standing up and curved upward then. Now I see, couldn't figure where the arch was. DUH! Was there only one layer of ply on the outside of the silo? What did you use for the stone siding? Now that the saucer has landed, will the trusses be exposed to the inside of the silo? Did you have the roofing on when you craned it in?

As you know, they can do some pretty awesome stuff with stucco. Seeing it used more & more around here.

|

|